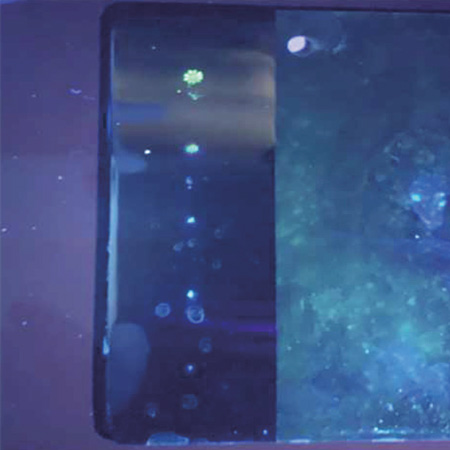

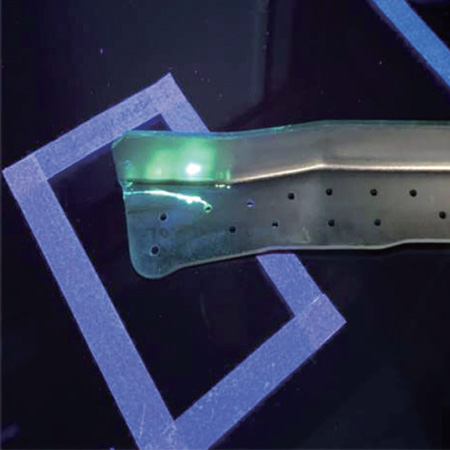

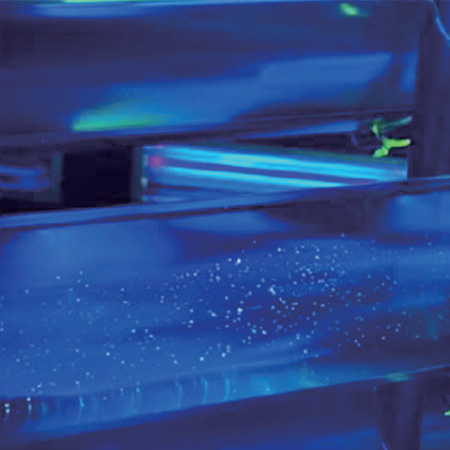

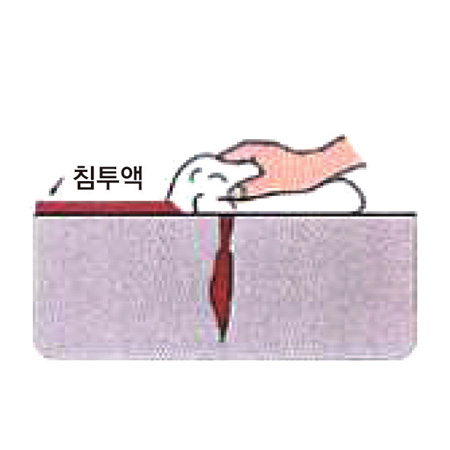

The process of filling the interior of the defect with a penetrating fluid using capillary phenomena

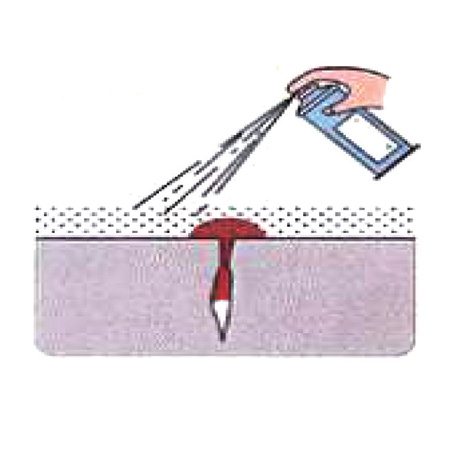

Process of removing any remaining penetration other than the defect

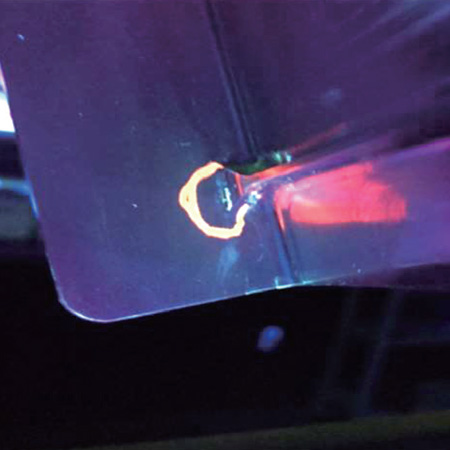

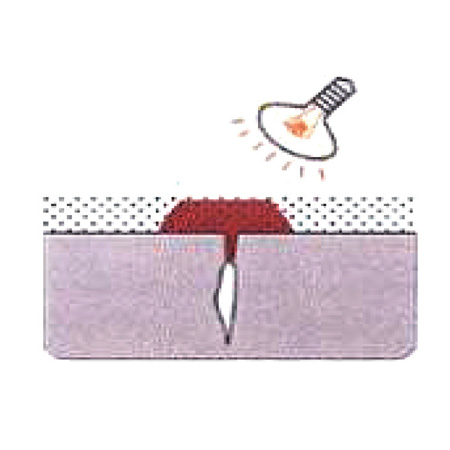

The process of obtaining the shape of an enlarged indication by extracting the penetrating fluid of a defect using a capillary phenomenon

The process of inspecting and reading the infiltrated indication under ultraviolet light

| Application field |

Defect inspection of processing (casting, machining, welding, etc.) Non-destructive inspercion of almost all materials including ferrous, plastic and non-ferrous metals Non-destructive inspection of parts in various industries such as the aerospace industry |

|---|---|

| Coating materials |

QPL-AMS2644

Penetrant : ZL-60D (Type I, Method A, Level 2) Developer : ZP-9F (Form D, Type I) Remover : SKC-S (Class 2) |

| Process condition |

Classification : Type I, Method A, Sensitivity Level 2 (Medium) Ambient Light : Darkroom (Max 20lux) White Light : White LED (10" to Min 1000lux) UV Light : EV6000 (1000 to 5000㎼/㎠ at 15” distance) |

| Process characteristics |

Detects defects without deformation or damage to the shape and function of the product Easy to detect porous defects such as fine cracks due to low surface tension and high capillary phenomenon of penetrating liquid Easy to measure the location and size of discontinuities by measuring the penetrating fluid area |